Silicone Molding

Silicone molding is a process used to create replicas or duplicates of an original object using silicone as the primary material for making the silicon mold. Common materials (in molten state) used to pour into the silicone molds are: Epoxy Resin, Casting Resin, Polyester Resin, Polyurethane.

About Silicone Molding:

-

Here are the pros and cons of Silicon Casting:

Pros:

Replication Accuracy: Highly accurate replicas, captures intricate details and textures of the original object with precision.

Versatility: Used with a wide range of materials, including resins, plasters, waxes, and more.

Durability: Silicone molds are known for their durability and longevity. They can withstand multiple casting cycles, making them cost-effective for producing multiple replicas.

Flexible Molds: Flexible in nature, easy removal of cast replicas without damaging them, and casting of complex and irregularly shaped objects.

Cons:

Air Bubble Trapping: During the pouring process, air bubbles can sometimes get trapped in the silicone mold, leading to imperfections in the cast replicas.

-

Do take note before you send us your files for the mould:

1. File format: .stl, .STEP, .3mf

2. File condition: Not broken (no empty spaces/dark shades on part).

3. If you have multiple files you would like to get quotations on, kindly:

Zip the files in a folder and send it to us for the quotation!

-

The silicone mold possesses a soft and flexible nature, allowing you to easily fill it with molten material. This characteristic enables the continuous production of accurate and efficient replicas.

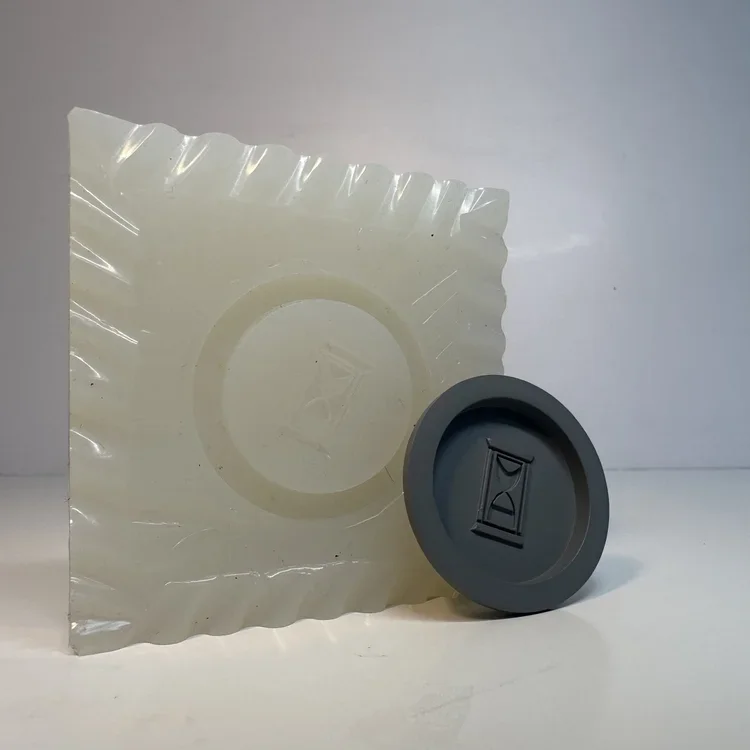

Click here to view an example of how a silicone mould looks like with the casted part.

-

Here are a few applications where you could use silicon casting to produce parts you desire:

Prototyping

Test pieces

Architecture & Decoration

Ornamental mouldings, columns, cornices

Jewellery

Charms, rings

-

Interested in Silicone Molding? Contact us