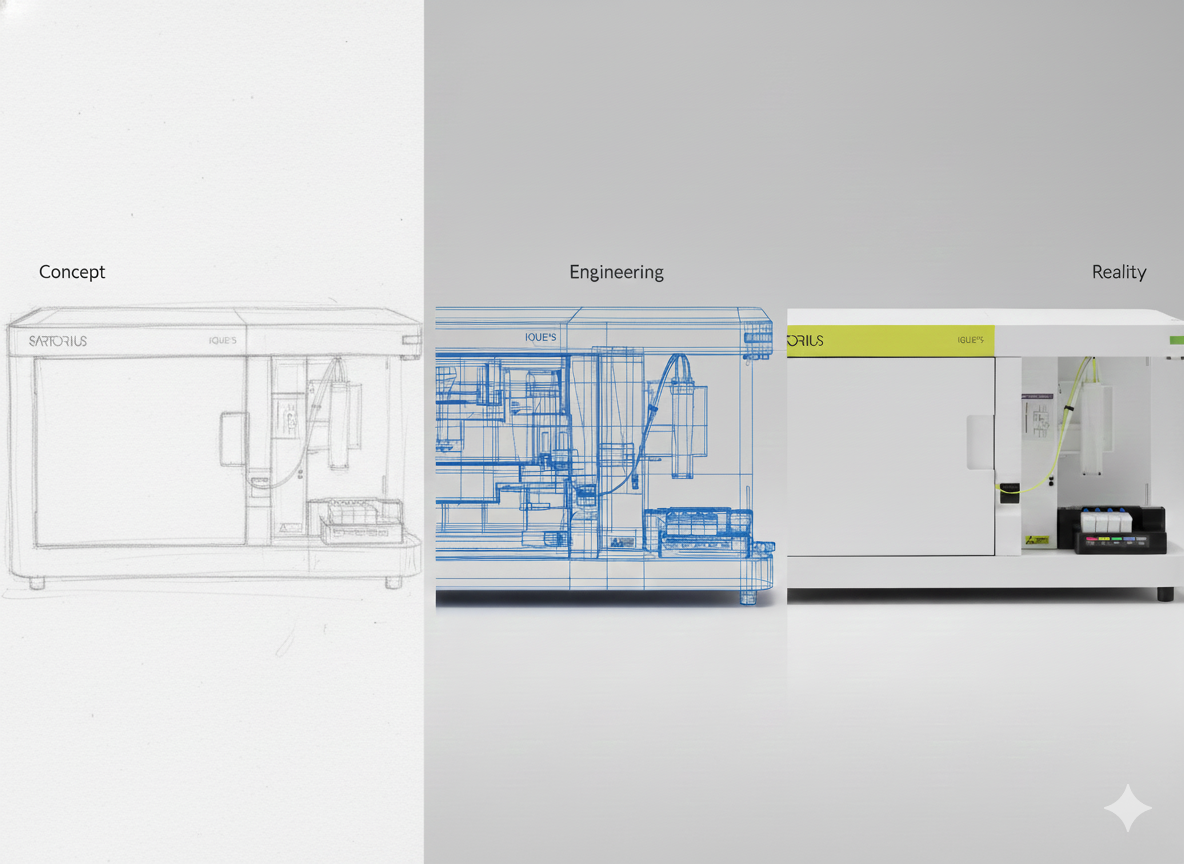

Concept to Fabrication

Bring your concept product to reality with us

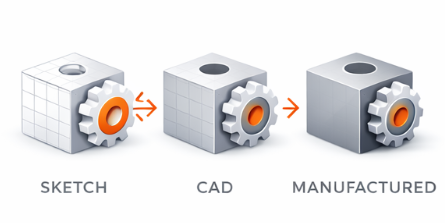

Our Concept to Fabrication Process

01 - Design for Manufacturing

You do not get pretty files that fail production. You get designs built for the chosen process, cost, and scale.

02 - Clear Cost and Trade-offs

You see what drives price early. We flag size, detail, material, and finishing before you commit.

03 - End-to-End Execution

You work with one team. Design, prototyping, fabrication, and scaling stay aligned.

04 - Built for Repeat and Scale

Files, settings, and decisions are archived. Reorders, updates, and production runs stay consistent.

What We Offer

We offer a range of services to meet the needs of every client. Have something else in mind? We'd be happy to work with you to create a custom quote.

-

You start with clarity. No guessing.

You share references, sketches, or a problem statement.

We define purpose. Display, functional, prototype, or production.

We lock constraints. Budget, quantity, timeline, finish level.

We advise feasibility early. We say yes, no, or adjust.

Outcome: clear scope. No surprises later.

-

Design follows manufacturing. Always.

Choose process first. FDM, SLA, SLS, MJF, CNC, casting.

Define material based on use. Strength, finish, heat, cost.

Decide detail level. Visual fidelity vs cost vs lead time.

Plan part breakup if needed. Assembly, tolerances, orientation.

Outcome: design direction that can actually be made.

-

This is where value compounds.

CAD built for printability, not just looks.

Wall thickness, fillets, draft, tolerances considered.

Branding and engravings integrated properly.

Files reviewed internally before moving forward.

You get:

Renders or screenshots for alignment.

Iterations scoped. No endless revisions.

Outcome: production-ready files.

-

No black box pricing.

We quote based on chosen process and material.

We flag cost drivers. Size, volume, post-processing.

We suggest optimizations if needed.

For overseas or China fabrication, we coordinate and verify.

Outcome: you know what you are paying for and why.

-

We print or fabricate with intent.

Correct machine and settings selected.

Orientation optimized for strength and surface.

Infill, layer height, and shells tuned to use case.

Batch planning done for consistency.

Processes include:

FDM for cost-effective and structural parts.

SLA for fine detail and smooth surfaces.

SLS or MJF for durable, production-grade parts.

CNC or casting when printing is not ideal.

-

Only what makes sense.

Support removal and clean-up.

Sanding, coating, or painting if required.

Assembly if scoped.

Quality check against agreed expectations.

We do not oversell finishes that do not add value.

Outcome: parts that match the brief, not marketing photos.

-

We close cleanly.

Photos shared for approval.

Delivery or self-collection arranged.

Feedback captured.

Files archived for reorders or scaling.

If it grows into production, we help you bridge there.

Past Project

Biotech Master Controller Replica

For this project, the goal was to build a fully accurate replica of the Biotech Master Controller for training, display, and demonstration use. The replica needed correct dimensions, a clean enclosure, and branded detailing that matched the original unit closely.

High Accuracy Modeling With Precise Fabrication

We recreated the entire enclosure through detailed 3D modeling, matching the surface geometry and panel layout from reference measurements. Each body panel was printed in controlled sections to maintain dimensional stability and reduce distortion during bonding.

The full print went through a complete surface preparation workflow. This included gap filling, sanding, and repeated priming to remove print lines and achieve a consistent finish. The front plate received additional attention to match the brushed metal tone of the real machine.

Brand elements such as the logo, labels, and indicator markings were applied only after the surface reached the correct texture. Positioning and scale were carefully aligned against the client’s reference photos to ensure that the front interface remained accurate.

Internal mounting points were reinforced to support long term handling and transport. Minor adjustments were made to improve durability without changing the visual layout of the original hardware.

The Result: A Reliable and Display-Ready Controller Replica

The completed replica delivers a clean, stable, and visually accurate representation of the Biotech Master Controller. The refined surface, precise modeling, and consistent branding make it suitable for use in demonstrations, showroom displays, and non-operational training.